How To Repair Filiform And Fretting Corrosion Control

| | |

| � Uniform � Galvanic � Crevice � Filiform � Pitting � Intergranular � SSC � LME � MIC � SCC � HB-HE-HIC � Fatigue � Erosion � Fretting � Alphabetize | |

Unlike Types of Corrosion | |

| Filiform Corrosion (Underfilm Corrosion) | |

| Recognition | |

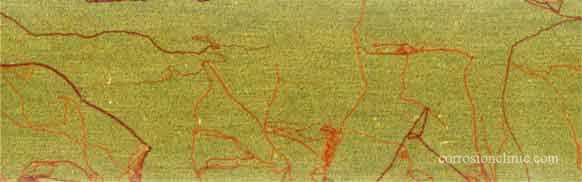

| What is filiform corrosion? Filiform corrosion is a special form of corrosion that occurs under some thin coatings in the form of randomly distributed threadlike filaments. Filiform corrosion is also known every bit "underfilm Corrosion" or "filamentary corrosion". How to identify filiform corrosion? Filiform corrosion occurs on metallic surfaces coated with a thin organic film that is typically 0.ane mm thick. The pattern of corrosion assault is characterized past the advent of fine filaments emanating from one or more sources in semi-random directions. The filaments are fine tunnels equanimous of corrosion products underneath the bulged and cracked coating. Filiform corrosion can exist visually recognized without using a microscopy. Filiform corrosion has been observed on surfaces of coated steel, magnesium, and aluminum with sparse coatings of tin can, silver, gilt, phosphate, enamel, and lacquer. Filiform corrosion has likewise been observed on paper-backed aluminum foils. | |

| Mechanisms | |

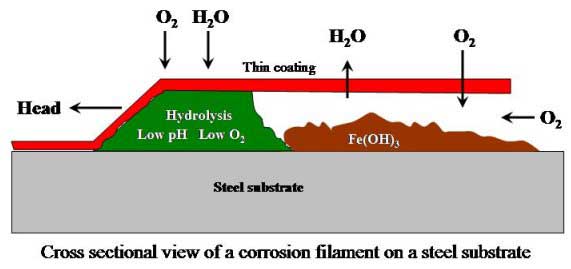

| What causes filiform corrosion? Filiform corrosion is a special case of scissure corrosion. During propagation, water is supplied to the head of the filament from the surrounding atmosphere by osmotic action due to the high concentration of dissolved ferrous ions on the surface of steel substrate. Osmosis tends to remove h2o from the inactive tail, because of the low concentration of soluble salts (iron has precipitated as ferric hydroxide). | |

| Prevention of Filiform Corrosion | |

| How to forbid filiform corrosion? Filiform corrosion or underfilm corrosion can be prevented with the post-obit methods:

| |

| For more details on Filiform Corrosion | |

| Where can I learn more than about devious current corrosion? More details on filiform corrosion or underfilm corrosion are included in the post-obit corrosion courses which you can take every bit in-business firm preparation courses, class-on-need, online courses or distance learning courses:

If you require corrosion good witness or corrosion consulting service on filiform corrosion, our NACE certified Corrosion Specialist is able to help. Contact united states for a quote. | |

| Habitation | Go to Superlative | Contact U.s.a. | PDF | Copyright � 1995-2022. All rights reserved. |

Source: https://www.corrosionclinic.com/types_of_corrosion/filiform_corrosion_underfilm_corrosion.htm

Posted by: jacobsonintelf.blogspot.com

0 Response to "How To Repair Filiform And Fretting Corrosion Control"

Post a Comment